Diagnostic Load Testing for Bridge Load Rating

Introduction

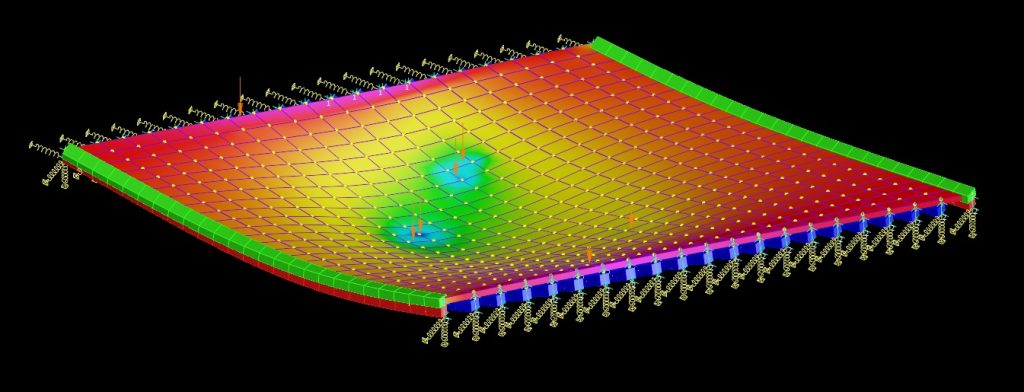

Ask any bridge engineer and they will tell you that a load rating is only as good as the assumptions that it’s based upon. When evaluating bridges, load ratings performed using traditional analysis methods can sometimes be overly conservative and result in unnecessary load restrictions. Section 8 of the AASHTO Manual for Bridge Evaluation (MBE) recognizes this, and outlines procedures for evaluating bridges using diagnostic load testing. Utilizing this more refined method allows engineers to calibrate the ratings with real world data to remove some of the conservatism built into standard assumptions and often improve bridge load ratings and/or remove load postings.

BDI’s History in Load Testing

BDI has lead the state of the practice of diagnostic load testing for more than 35 years, helping countless bridge owners reduce restrictions or remove postings on their structures using our load testing and analysis methods, but even we can admit that load testing is not the right solution for every bridge. In our extensive experience, load testing is best suited to structures where changes in key structural characteristics have potential for adjustment, as explained in the next section.

Structural Characteristics Best for Load Testing

- Effective structural stiffnesses

- Load resistance is highly correlated with the stiffness of the structure, which can vary based on actual material strengths, structural dimensions, or contributions from secondary/nonstructural members (such as curbs or bracing). When reliable sources of additional stiffness are found through load testing measurements, the structure capacity typically increases and so does the overall load rating.

- Load path and distribution

- This is often where we see the greatest benefit. For structures with multiple primary members or high redundancy (e.g., multi-girder bridges), load testing measurements typically show that these members share load more effectively than code-based calculations suggest. As such, each member is subjected to a lower overall load effect and in turn an increased load rating.

- Composite action and span continuity

- Depending on the construction of the bridge, composite action and/or span continuity can exist where it is not expected (often due to friction). Load testing can also determine whether a bridge’s girders were constructed compositely with the deck if design information is unknown. These changes dramatically affect how the structure is analyzed, and therefore often generate significant improvements to load ratings.

Concluding Thoughts

Diagnostic load testing, with real world data input from sensor measurements, allows BDI to reduce the number of assumptions applied to bridge analysis. The refined analysis results in high-quality, field-verified bridge load ratings that consider a multitude of factors not captured in standard load ratings. If you still aren’t sure whether diagnostic load testing is right for your structure, contact us today and our experts can help determine what benefits you might be able to expect from our services.