Pre & Post-tensioned Concrete

Assessing concrete with embedded pre-stressed/post-tensioned (PS/PT) elements (strands or tendons) is more challenging than conventional concrete structures, as the reinforcement and ducts are hidden and not readily accessible. BDI delivers cutting-edge PT concrete inspection and evaluation services through a fusion of nondestructive testing (NDT), diagnostic testing and monitoring, and engineering analysis.

What We Measure

BDI employs the complementary use of several advanced NDT-E techniques and physical verification to improve the accuracy and reliability of embedded PT duct inspections.

-

As-built verification

-

Condition assessment

Ground Penetrating Radar (GPR)

Ground Penetrating Radar (GPR)

Ultrasonic shear wave tomography (MIRA)

Ultrasonic shear wave tomography (MIRA)

Destructive verification

Destructive verification

Determine the location of the ducts for lightly to moderately reinforced regions

Determine the location of embedded PT ducts and PS/PT strands for heavily reinforced regions. Tomography is a great tool to locate multiple layers of strands.

To inspect internal PT tendons, BDI creates small access points to visually examine the ducts using a borescope camera. This allows direct visual verification of concrete cover, diameter and material of PT ducts, diameter of strands, number of strands and wires, etc. This remote opening can also be used to evaluate potential structural issues like corrosion or unintended air gaps in grouted ducts.

Impact Echo

Impact Echo

Ultrasonic shear wave tomography (MIRA)

Ultrasonic shear wave tomography (MIRA)

Borescope visual inspections

Borescope visual inspections

Material testing

Material testing

Monitoring

Monitoring

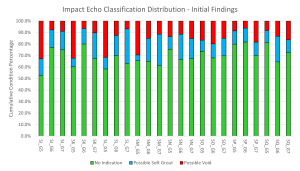

Fast point-by-point method used to screen large areas and identify potential voids or presence of soft grout.

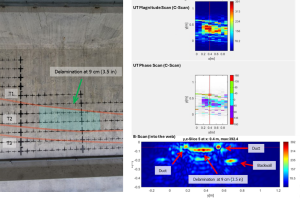

MIRA is an advanced ultrasonic tomography tool used to detect defects inside grouted PT ducts. It creates 2D and 3D images of internal concrete conditions using shear wave pulses—helping identify hidden issues like poor grout, delaminations, or honeycombing.

To inspect internal PT tendons, BDI creates small access points to visually examine the ducts using a borescope camera. This allows direct visual confirmation of grout conditions, voids, strand condition, and signs of corrosion.

The presence of chlorides, sulfates, and moisture in the grout system can lead to the degradation of the steel tendons or the formation of soft grout.

BDI employs a suite of sensors and data acquisition equipment designed to monitor PT concrete structures in real time. These tools track a variety of parameters, such as temperature, crack activity, stress, and corrosion risk—helping ensure long-term performance, safety, and early detection of potential issues.

What We Deliver

Beyond standard narrative reporting and conclusions, BDI provides:

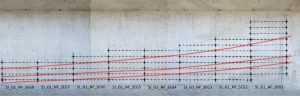

Whether you're clearing the embedded PT for coring or verifying cover and spacing, GPR and MIRA results include visual markings, layout maps and reports to clearly delineate the as-built configuration of your PT.

BDI develops CAD maps to overlay results of its NDT-E services on the structure under investigation, with clear color-coded findings and reference photographs.

BDI’s analysis uses aggregate stats and summary tables to highlight key insights of your structure. Quick, clear, and actionable insights that drive smarter decisions.

Deliverables include a detailed report with opening locations, annotated photos, borescope images (if applicable), and notes on condition observations such as grout condition, strand corrosion, and presence of voids.

Ground Penetrating Radar (GPR)

Ground Penetrating Radar (GPR)