During a routine river lock outage period, the client detected potential emergency problems with gudgeon anchor components on the south downstream lock gate. One important aspect of this project was the critical time constraints for BDI to prepare and mobilize to the site since the issue was discovered near the end of the standard lock outage period. BDI was notified on a Monday about the project and had six days to prepare and mobilize to the site for testing the following Monday. BDI was subcontracted by to perform emergency instrumentation and monitoring on these critical miter gate supporting frame members.

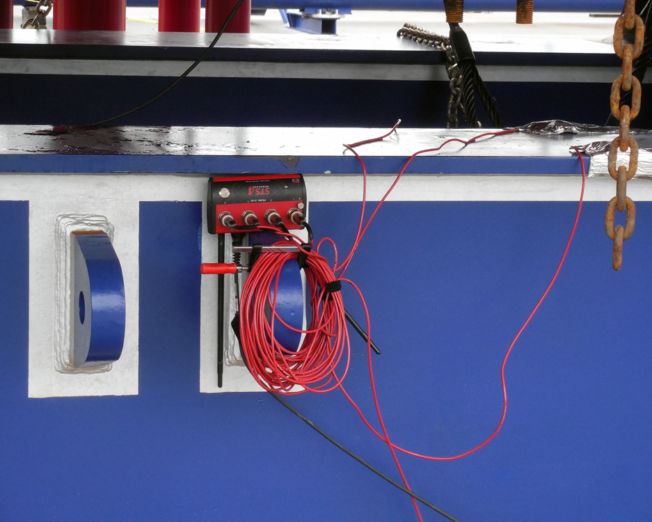

The scope of work included installing both temporary and permanent strain gages on the gudgeon assemblies and monitoring all instrumentation during several full gate swinging and lock chamber cycles. Rotation sensors were also installed to record the gate positions and water level positions were tracked with a manual “clicker” system connected to the BDI datalogger. All data was formatted into Excel spreadsheets by BDI Registered Professional Engineers and submitted to the prime contractor and client. The results of these tests led the client to extend the river lock outage and to perform immediate retrofits on the gudgeon assemblies.