We are also a representative for  and supply their full range of products.

and supply their full range of products.

Custom Strain Gages

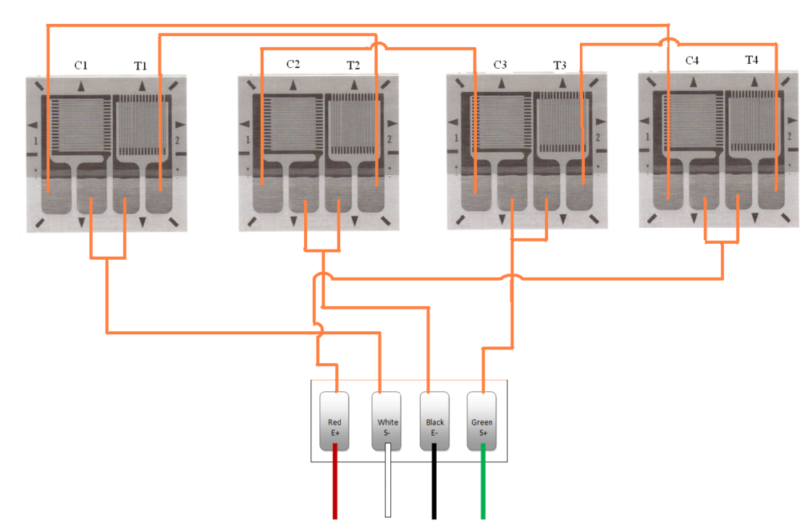

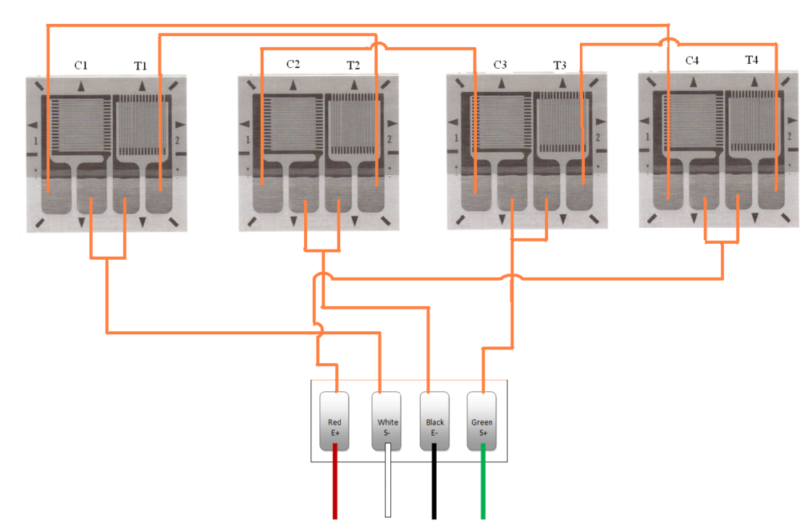

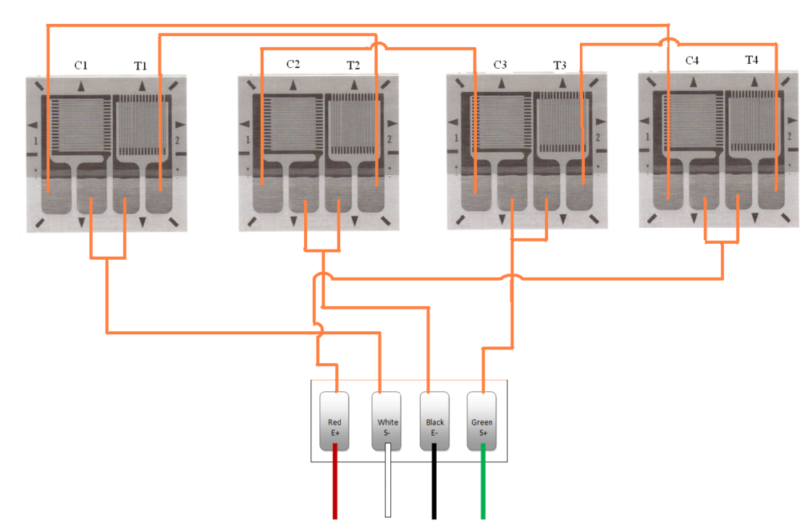

We provide custom-built strain gage load measuring devices to suit specific applications. Our team has more than 30 years’ experience in the design, fabrication, and calibration of these devices based on a Wheatstone bridge design using resistance strain gages. The Wheatstone bridge configuration allows for a dynamic response, increased sensitivity, better temperature compensation, and elimination of bending effects over using a single strain gage. This technology can be used to design custom-built load cells or turn existing load hardware into calibrated measuring devices. Our engineers and technicians are trained in ‘Transducer-Quality’ strain gage installation techniques to eliminate the potential of long-term measurement drift and provide the accuracy, durability, and longevity required in construction applications.

300-kip Load Cells

The design of the resistance strain gage load cell eliminates the need for large end bearing plates often required for vibrating wire load cells. Load cells are designed using 8-gage Wheatstone bridge configuration around the circumference of the load cell body to greatly reduce effects of eccentric loading. Each load cell is individually calibrated to NIS-traceble standards and come with calibration records and QA documentation. Custom design can also include external handles, plug connectors or built-in shunting capabilities depending on application needs.

4500-kip Load Measuring Bearings for Bridges

Working with Colorado DOT to measure and evaluate dynamic load capacities of rock fall netting designs, load links for netting cable hardware were instrumented with Wheatstone bridge resistance strain gages to turn existing cable/anchor hardware into accurate load measuring devices. Links were pre-calibrated prior to installation and provided dynamic load response at anchor points throughout the netting for load distribution during staged rock drops.

200-kip Load Measuring Links for Rock fall Netting

We designed load measuring turnbuckles using existing support hardware for Highway wall systems in front of Geosynthetic Reinforced Soil (GRS) abutments. Concerns for load distribution on support system during backfilling operations were mitigated through this strain-gaged, load measuring system without disturbing the load framing system. The Wheatstone bridge circuit design eliminated potential bending measurements and provided temperature compensation of measurements.

10-kip Load Measuring Turnbuckles for Bridge Abutments

Working with Colorado DOT to measure and evaluate dynamic load capacities of rock fall netting designs, load links for netting cable hardware were instrumented with Wheatstone bridge resistance strain gages to turn existing cable/anchor hardware into accurate load measuring devices. Links were pre-calibrated prior to installation and provided dynamic load response at anchor points throughout the netting for load distribution during staged rock drops.

WORK WITH US

Learn more about the strain gage services we offer