What is Construction Monitoring?

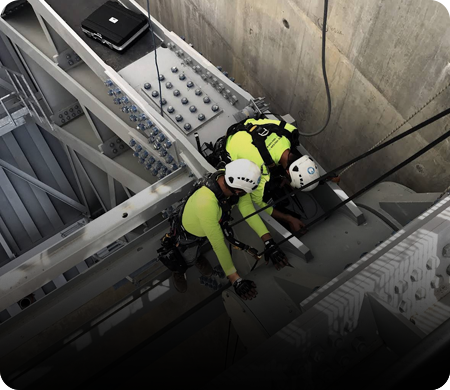

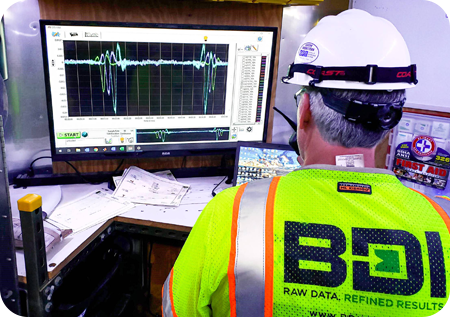

Construction activities like blasting, pile driving, excavation, etc. can introduce risk to the site, to surrounding structures, to infrastructure, and to the public. At BDI, we offer a suite of data-backed monitoring strategies designed to help contractors and owners manage these risks with confidence.

What We Measure

Depending on the type of construction activity, structure, or area at risk, construction monitoring can consist of a variety of measurements for investigating construction effects. Our team provides expert guidance to define the appropriate monitoring scope, always selecting the best tool for the job, often utilizing our specialized long-term monitoring system. Depending on desired results could include monitoring of:

-

Construction Monitoring

Settlement Detection

Settlement Detection

Vibration Monitoring

Vibration Monitoring

Crack monitoring

Crack monitoring

Pre- and Post-Construction Condition Inspections

Pre- and Post-Construction Condition Inspections

What We Deliver

Innovative Solutions

We’ve assisted many contractors and owners alike in managing risks to safety and serviceability throughout all types of construction. See below to explore some of our construction monitoring portfolio, then contact us to help develop a custom monitoring solution for you.

Settlement Detection

Settlement Detection