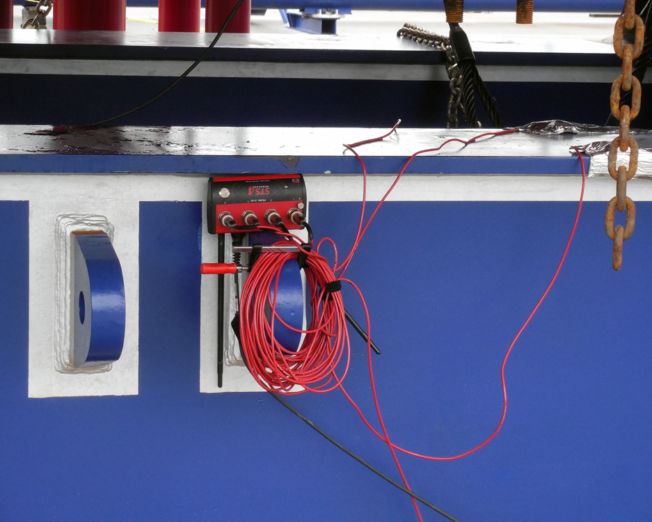

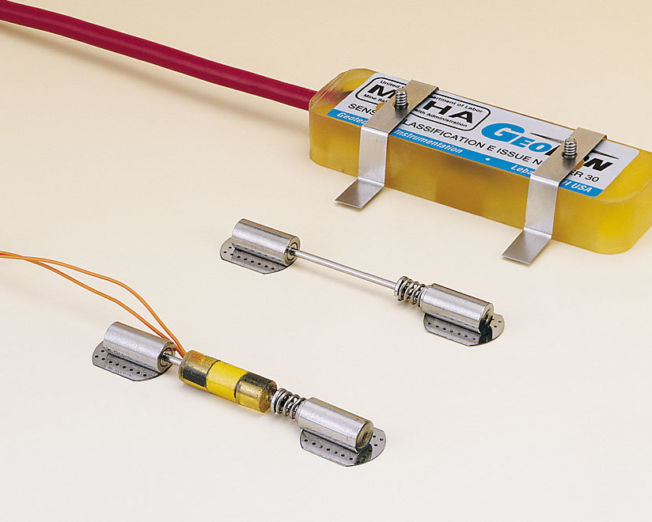

During routine nondestructive testing of the pin/hanger assemblies on a bridge in the Mid-Atlantic region, BDI obtained irregular results on two of the pins. It was not immediately known what the defect was within the pin so the structure was load posted for 15 tons until a load test and monitoring could be added to the catch system. Within 48 hours of discovering the abnormality, BDI designed, built, and installed a wireless strain gage monitoring system on the catch system and has been conducting ongoing monitoring. All of the data was transmitted to BDI’s monitoring website and displayed on PI, a web-based platform. The system is also providing alerts via SMS, email, and telephone call if/when thresholds are exceeded. Once the construction was complete, BDI removed all instrumentation.

Further, BDI is currently working with the DOT to expand this monitoring system to a full scale SHM system for the remaining catch systems and other deficient members.