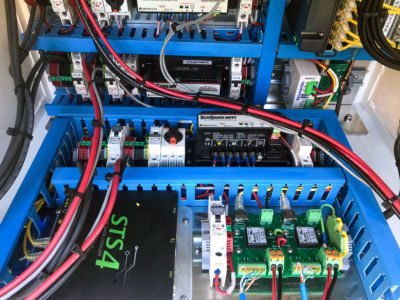

BDI was contracted to provide the design, installation, and commissioning/operation of structural health monitoring systems (SHM) for two bridges. The SHM system includes weldable strain gage rosettes, weldable uniaxial strain gages, custom designed ladder-style crack propagation sensors, thermistors, weather stations, traffic cameras, acoustic emissions sensors, and loop and piezo traffic classifiers. Data provided will classify truck traffic, photograph the vehicle classified and correlate truck classification to strain readings on structure. Acoustic emissions sensors were used to quantify development of cracks in critical regions of the structure wile the BDI-designed crack propagation sensors were utilized to track the growth rate of known existing cracks. The period of performance for structural health monitoring systems is initially one year. The measurements recorded on site, while accomplished with four independent data acquisition systems (SHM, AE, Traffic, and Cameras), are integrated through BDI’s core datalogger and are synchronized wirelessly to BDI’s Platform Interactive (PI) cloud-based visualization platform. Through PI, the entire project team will be able to view the near real-time status of the structure and any events generated from the measured responses.